-

connect with us

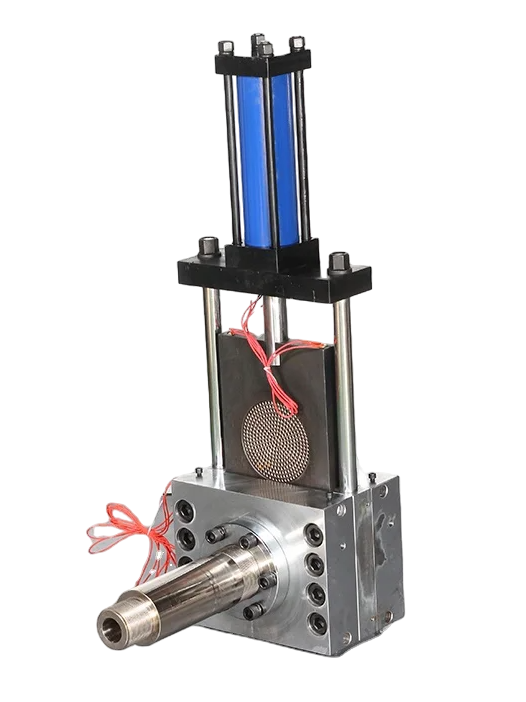

Hydraulic Screen Changers

Hydraulic screen changers are devices used in plastic extrusion processes to remove contaminants and filter out impurities from the molten plastic as it passes through the extruder. They are a type of screen changer that utilizes hydraulic pressure to facilitate the changing of screens during operation.

The basic principle of a hydraulic screen changer involves the use of multiple screens or filter media arranged in housing. The molten plastic flows through these screens, which trap contaminants and particles while allowing the clean plastic to pass through. Over time, as the screens become clogged with impurities, they need to be replaced or cleaned to maintain desired flow rate & product quality.

Advantages

- Very Special sealing leak proof system ensures smooth operation.

- Seal-Less Design

- Equipped with concealed wiring, safe guarding & protection

- High tempreture resistance painting on machine up to about 400 degrees.

- Heavy duty spcially designed hydraulic cylinder with self allignment systems.

- Machine mount on heavy base fram.

Key components of Hydraulic screen changer include:

-

Screen Pack :

This consists of multiple screens or filter elements arranged in a stack within screen changer housing. The screens are typically made of stainless steel or other durable materials capable of withstanding high temperatures & pressures. -

Hydraulic Piston Assembly :

Hydraulic piston assembly applies pressure to push the used screens out of flow path & introduce new screens into position. It is controlled by a hydraulic system that regulates pressure & timing of screen changes. -

Manifold & Sealing System :

The manifold directs the flow of molten plastic through screen pack, while sealing system ensures a tight seal between screens and the housing to prevent leakage & maintain pressure. -

Control System :

It regulates the operation of hydraulic screen changer, including timing & pressure of screen changes. It may be integrated with extrusion line's overall control system for seamless operation.

Hydraulic screen changers are commonly used in various extrusion processes, including film and sheet extrusion, pipe and profile extrusion & compounding. They help to improve product quality by removing contaminants and maintaining consistent flow rates, leading to higher productivity and reduced downtime for screen maintenance.