-

connect with us

EXTRUDER- SCREW AND BARRELS

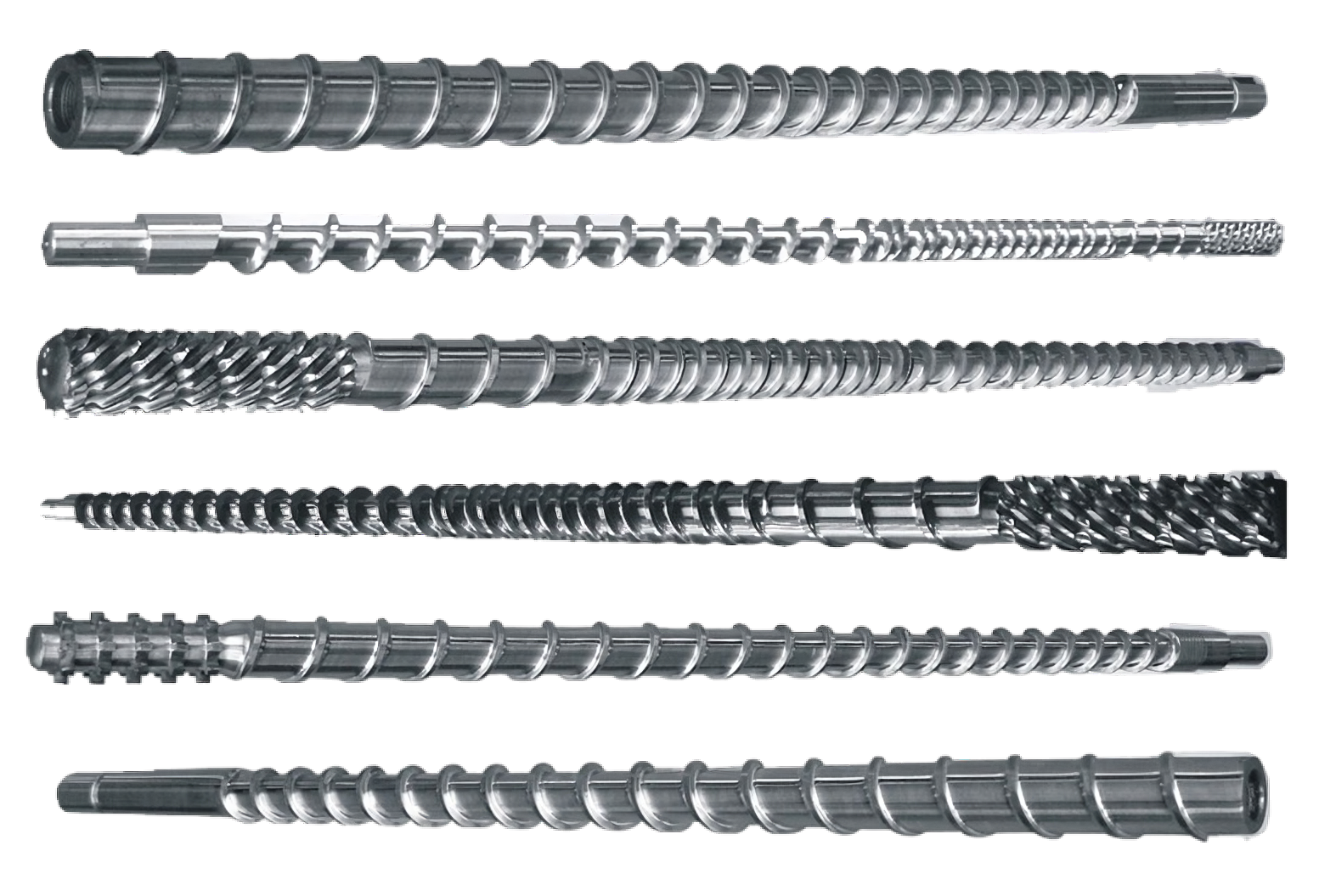

An extruder consists of a screw and barrels, essential components for the plastic extrusion process. The screw rotates within the barrels, transporting & melting the plastic resin as it moves along the barrel length. The design of the screw and barrels, including their geometry, materials & surface coatings, influences the extrusion process's efficiency, melt quality & throughput.

These components play a crucial role in controlling parameters such as temperature, pressure, and mixing, ultimately determining the quality and properties of the extruded plastic product.

Pin Mixer

Dulmage Mixer

Maddoc Mixer

Saxon Mixter

Pineapple/Saxton Mixer

Egan Mixture

Slotted Screw Flight

Blister Ring

| Property | Value |

|---|---|

| Material | Nitrided Steel EN-41B Material, Standard 38CrMoAIA (JIS SACM645); 42CrMo (AISI4140) Cr12MoV (JIS SKD11); 4Cr5MoSiV1 (JIS SKD-61) |

| Nitrided Hardness | HV950°-1050° |

| Hardness after hardening & tempering | HB260 -290° |

| Nitrided Depth | 0.5-0.9mm |

| Nitrided Brittleness | Less than Grade 2 |

| Surface Roughness | Ra0.4 |

| Screw straightness | 0.015mm |

| Hardess of surface chromium-plating after Nitriding | HV>=950HV |

| Chromium plating Depth | 0.05-0.10mm |

| Alloy Depth | 3-5mm |

| Alloy hardness | HRC56° - 65° |

| Alloy (bimetallic) | iron nickel tungsten,molybdenum |

| Types of extruder screw barrel extruder screw barrel | Gradual type mutanttype wavetype barriertype double screen type, shunttype, separationtype, exhausttype, pintype, mixedtype, double-head type, three-head type, multi head type, etc. |

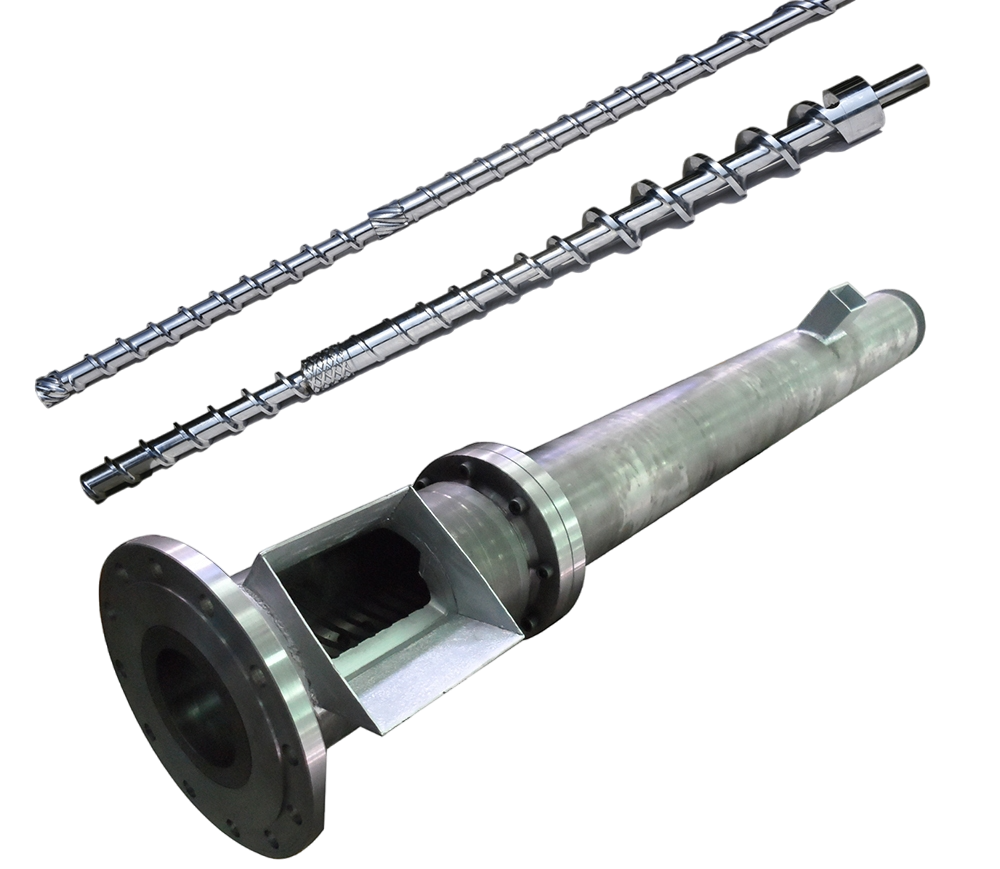

1. SINGLE SCREW AND BARREL SET

A single screw and barrel set is a core component of extrusion systems, where the rotating screw within the barrel conveys, compresses, and melts materials like plastic. It's crucial for various extrusion applications, determining factors such as output rate, melt quality, and energy efficiency.

Single Screw Features:

- Dimensional accuracy in tolerance of ±0.02

- Custom Design to meet specific needs.

- Polishing for enhanced resistance & longevity surface finish.

- Higher output capacity and Longer life span.

- Extraordinary surface hardness with TC Coating (Depth 1.5 to 2mm).

- Accurate linearity of scew. (<0.02mm/m)

Single Barrel Features:

- Higher Output.

- Accurate compatibility with Die and Gare Box

- Precise positioning of barrel bore & smooth finishing.

- Bore inspection with precision gauging machine.

- Extraordinary wear-resistance by Nitriding.

2. VENTED SCREW AND BARREL

A vented screw and barrel set is tailored for materials releasing gases during extrusion. It is best suitable for recycling of PP?HD/HIPS/PC/ABC and other engineering compounds. It is used for degassing of moisture and volatile through vent.

Vented Screw Barrel ensure proper venting without causing any leakage issue. The screw is designed for maximimum efficiency and maximimum mixing in conveying of the material with negligible heat at desired rate.

.jpeg)

3. SINGLE BARRIER SCREW AND BARREL

Barrier screws are a way to increase throughput of single-screw extruders and to improve melt quality. It's crucial for various extrusion applications, determining factors such as output rate, melt quality, and energy efficiency.

A single screw & barrel set is core component of extrusion systems, where rotating screw within barrel conveys, compresses & melts materials like plastic. This eliminates unnecessary degrdation also improved rate & melt quality and lower melt temprature.

It is suitable for PVC Pipe (Right/Flexible), PVC profile, PVC cable, ABC, Polythelene.

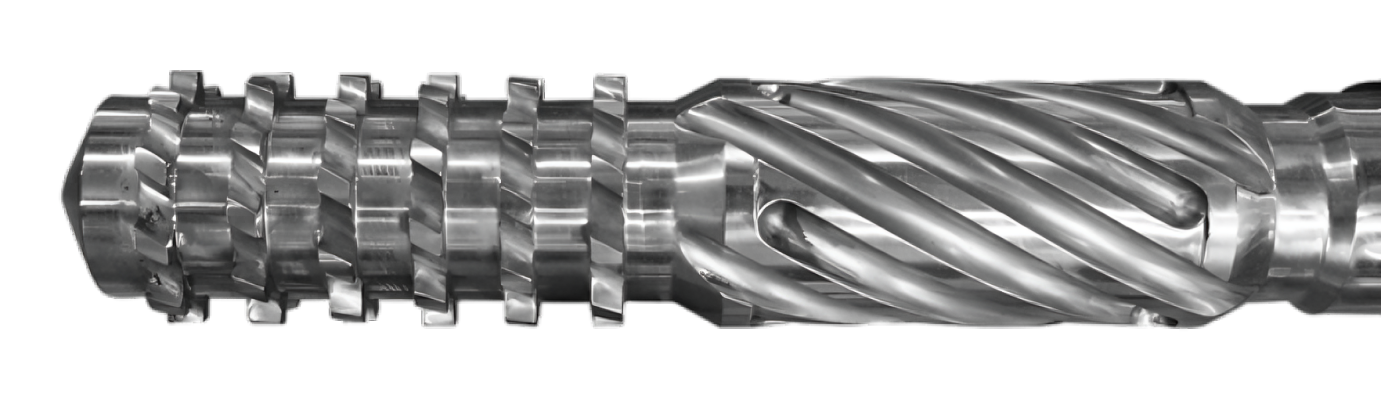

4. MADDOC BARRIER SCREW AND BARREL

We are providing and extensive range of Maddoc Barrier Screws that are made using high quality nitro alloy material and have a barrier design. Its setup improves mixing & melt quality in extrusion. Barrier flights along the screw divide material flow for better dispersion, enhancing homogeneity and product quality.

This Screw is specially designed for materals that require rigorous mixing suitable for HDPE pipe, XLPE Cable, Lay Flat pipe, LLDPE Tubing, PP Film, HM.

5. CUSTOM SCREW AND BARRELS

Custom screw and barrels are specialized components designed for specific extrusion needs. Tailored parameters like geometry and material composition optimize performance and product quality in various applications, from plastics to food processing.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)