-

connect with us

Auxiliary

Auxiliary machines refer to various equipment and tools used alongside the primary extrusion machinery to enhance the efficiency, quality, and versatility of the extrusion process. These auxiliary machines play critical roles in different stages of extrusion, from material preparation to product finishing.

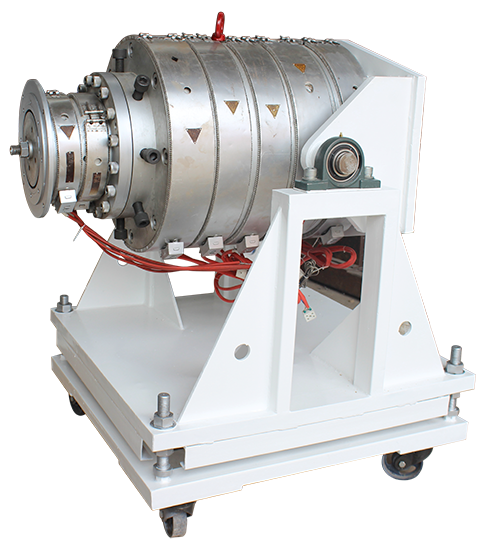

Groove Feed Sleeves Screw - Barrel

Some Barrel features of Groove Feed Sleeves Screw

- Unmatched Melting Efficiency: Experience exponential throughput increases with optimized heat transfer & flow dynamics.

- Boosted Production Capacity: Unleash the full potential of your operation with exceptional output rates.

- Long Duration

- Corrosion resistant

- Precise measurement

- Unwavering Quality Assurance

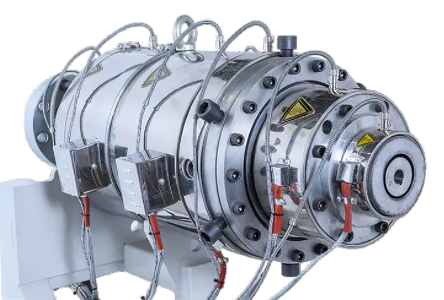

Blow Film Extrusion Die Head

The Blown Film Extruder die head is referred to as the "HEART" or core component of plastic film blowing machine. Die Head's main purpose is to spread the melted polymer uniformly so that the tube's circumference thickness measurement is accurate.

The molten polymer flows easily through the Die Head of a well-designed blown film die, with none of the polymer remaining inside.

We can produce die head as customers required and also professionally for the die head of a film blowing machine, with various dimension sizes and requirements.

Pipe Extrusion Plant Die

RPVC Pipe Extrusion Plant Die

Features:

- Uniform distribution of melt across the whole circle of the pipe.

- A wide range of thickness is guaranteed by high-volume, low-pressure design.

- For greater outputs in smaller diameters, use two die heads.

- Even with smaller pipes, extruder utilization ranges from 80–100%.

- For delicate material, the ideal residence time profile includes selective temperature control.

- Better mechanical qualities of pipe are made possible by removing of continuous spider markings (ID to OD).

Specification :

| Model | Unit | W-63 | W-110LV | W-110HV | W-200LV | W-200HV | W-250 | W-315 |

|---|---|---|---|---|---|---|---|---|

| Pipe Size | mm | 20-63 | 20-110 | 20-110 | 32-200 | 63-200 | 75-250 | 90-315 |

| Output | Kg/hr | 100 | 200 | 250 | 250 | 320 | 425 | 550 |

HDPE Pipe Extrusion Plant Die

Features:

- Decreased purging duration and an improved inner pipe surface.

- Controlling both the melt temperature & compression ratio becomes easy by optimal back pressure.

- Achieving uniform melt flow can result in small amount of variation in wall thickness.

- Allows for the processing of PE, PPR, & ABS with just a tooling change.

- Uniform processing properties across the entire material spectrum.

- Low melting temperature & minimal pressure build-up even at high throughput.

Specification :

| Model | Unit | WM-50 | WM-110 | WM-200 | WM-250 | WM-450 |

|---|---|---|---|---|---|---|

| Pipe Size | mm | 12-50 | 20-110 | 20-200 | 63-250 | 90-450 |

| Output | Kg/hr | 200 | 350 | 500 | 800 | 1000 |